I-DT(G) Itheminali yokuxhuma yethusi

Ipharamitha yomkhiqizo

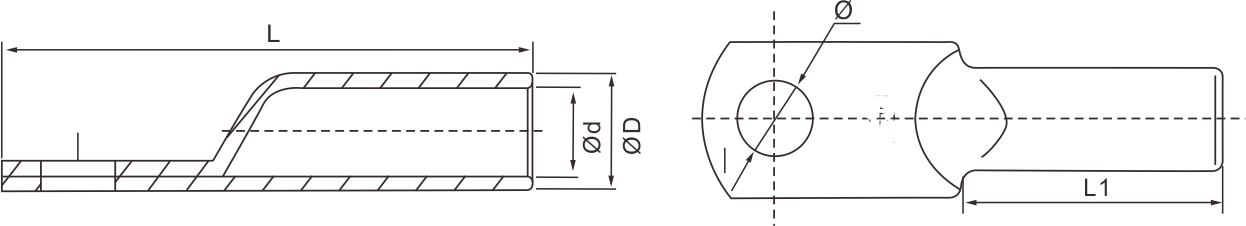

| Uhlobo | Ø | D | d | L | L1 |

| I-DT(G)-10 | 6.5 | 8 | 5 | 51 | 28 |

| I-DT(G)-16 | 6.5 | 9 | 6 | 57 | 32 |

| I-DT(G)-25 | 8.5 | 10 | 7 | 61 | 32 |

| I-DT(G)-35 | 8.5 | 11 | 8.5 | 66 | 36 |

| I-DT(G)-50 | 8.5 | 13 | 10 | 72 | 38 |

| I-DT(G)-70 | 10.5 | 15 | 12 | 80 | 43 |

| I-DT(G)-95 | 10.5 | 18 | 14 | 85 | 44 |

| I-DT(G)-120 | 12.5 | 20 | 15 | 97 | 51 |

| I-DT(G)-150 | 12.5 | 22 | 17 | 102 | 53 |

| I-DT(G)-185 | 14.5 | 25 | 19 | 113 | 54 |

| I-DT(G)-240 | 16.5 | 27 | 21 | 118 | 56 |

| I-DT(G)-300 | 16.5 | 30 | 24 | 128 | 62 |

| I-DT(G)-400 | 21.0 | 34 | 26 | 150 | 65 |

| I-DT(G)-500 | 21.0 | 38 | 30 | 170 | 70 |

| I-DT(G)-630 | 21.0 | 45 | 35 | 200 | 80 |

Njengohlobo lwesixhumi, itheminali iyingxenye ebalulekile embonini kagesi.Idlala indima engeke ithathelwe indawo nenganganakwa.Ngoba onjiniyela nochwepheshe baqale bahlole isixhumi esibonakalayo ngesikhathi sokulungiswa.Okusho ukuthi, itheminali iqala ngetheminali.Umklamo ubaluleke ngokukhethekile.

Kulula futhi kulula ukuyisebenzisa.Udinga kuphela ukuyicindezela nge-vise ukuze uqedele ukuxhumana.Ungakwazi ukufaka intambo ngokuqondile emgodini wezintambo wetheminali, futhi uxhumano lungaqedelwa ngokucindezela noma ukuphotha ngesenzo esisodwa esilula.Uma ifakwe izintambo ezikhethekile zokuxhumanisa, umphumela ungcono, ngokushesha, futhi izinga lokuxhuma liyi-100%, elidlala indima ebalulekile kumaphrojekthi wocingo kanye nenethiwekhi.1. Indlela yokuxhuma i-Screw block block

Uxhumano lwe-Screw luyindlela yokuxhumana esebenzisa amabhulokhi wesikulufa esibulalayo.Naka ubuningi bezingxenye eziphambanayo nezincane zezintambo ezivunyelwe ukuxhunywa, kanye ne-torque ephezulu yokuqinisa evunyelwe yizikulufu zokucaciswa okuhlukile.2. Indlela yokuxhuma i-welding ye-terminal block

Uhlobo oluvame kakhulu lwe-soldering luyi-soldering.Into ebaluleke kakhulu ekuxhumekeni kwe-soldering ukuqhubeka kwensimbi phakathi kwe-solder kanye nobuso obuzothengiswa.Ngakho-ke, i-solderability ibalulekile kumatheminali acindezelwe abandayo.Izingubo ezivame kakhulu ohlangothini lwe-solder lwetheminali yendandatho yocingo yi-tin alloy, isiliva negolide.Othintana naye wohlobo lomhlanga unohlobo lwesiqephu se-welding, uhlobo lwe-punching welding piece kanye nohlobo lwe-notched welding piece lokuphela kwe-welding evamile: othintana naye we-pinhole unohlobo lwe-notch ye-arc yokubhoboza ekugcineni kwe-welding evamile.3. Indlela yokuxhuma i-Crimping ye-terminal block

I-Crimping iyindlela yokucindezela nokukhipha insimbi ngaphakathi kwemingcele ethile kanye nezintambo zokuxhuma kumapheya okuxhumana.Uxhumo oluhle lwe-crimp lungakhiqiza ukugeleza kwe-metal mutual fusion, ukuze ucingo kanye nezinto ezithintana naye ziwohloke ngokulinganayo.Lokhu kuxhumana kufana noxhumo olunama-welded abandayo, olungathola amandla angcono emishini nokuqhubeka kukagesi, futhi lungamelana nezimo zemvelo ezinzima kakhulu.4. Indlela yokuphefumula ye-terminal block

Ukuvunguza ukusonga intambo ngokuqondile ku-angular contact winding posting.Ngesikhathi sokusonteka, ucingo lulinyazwa ngaphansi kokucindezela okulawulwayo, bese lucindezelwa luphinde lumiswe emakhoneni eposi elijikayo lesiqephu sokuxhumana ukuze kwakheke ukuthintana okubamba umoya.